Sales data reports are invaluable for decision-making. These insights provide information on which of your products are popular, simply aren’t selling, or are moving slowly.

When you track sales based on customer demand and seasonality, you get in-depth inventory analysis. Better inventory control can help you:

- Keep track of inventory counts across all sales channels

- Time reorders

- Optimize order quantity

- Reduce carrying costs

- Improve cash flow

- Increase profitability

Recommendation: You can use data to base decisions on facts instead of assumptions or estimates. While personal experience guides choices, pure sales information will help, too. Check out this guide to inventory analysis for more information.

5. Calculate and optimize reorder points

A reorder point is the level where it's most efficient to submit a supplier order to restock your inventory on a particular item. Knowing your ideal reorder point tells you when to place an order so you don't run out of stock or carry excess inventory.

If you have a great product on your shelves that sells fast, every purchase means more revenue. However, it also lowers your inventory levels. Reorder too early, and you'll need to spend more on storing excess items. Order too late, and you could face disappointed customers.

Recommendation: Optimize your reorder points to reduce excess spending and ensure you have enough stock for your customers. Use the below formula to determine your reorder point.

You can also try QuickBooks Advanced Inventory for automation-assisted reorders.

How to calculate your reorder point

- Calculate your lead time demand in days—this is how long it takes for your vendor to fulfill your order.

- Calculate your average daily usage—this is the number of sales made in an average day of that particular product.

- Calculate your safety stock—this is the amount of extra stock that you keep in your inventory.

- Multiply your lead time in days by your average daily usage.

- Add the result to your safety stock to determine your reorder point.

Reorder point equation

(Lead time in days x Average daily usage) + Safety stock

Reorder point example

Let’s say you’re a retailer and you sell 50 headbands per day. Your vendor takes five days to deliver each reorder. You keep a safety stock of 250 headbands, or five days of sales. In this case, the formula is:

(5 lead time days x 50) + 250 safety stock headbands = 500

When there are 500 headbands left in your inventory, it’s time to reorder.

6. Conduct regular inventory cycle counts

A cycle count involves counting a small amount of inventory on a specific day without doing an entire manual stocktake. Instead, it's a sampling technique that lets you see how accurately your inventory records match what you have on your shelves.

Recommendation: How often you do a cycle count and how much stock you count will depend on the types of products you sell and the resources at your disposal. Regardless of your specific approach to inventory counts, here are some best practices to follow:

- Count one product category at a time

- Choose count categories based on seasonality

- Mix up your cycle count schedule

There are three main types of inventory cycle counts that you can use:

Control group cycle counting

This type of cycle counting focuses on counting the same items repeatedly over a short period. The repeated counting reveals errors in the count technique which you can then rectify to design an accurate count procedure.

- Best for: Streamlining your cycle count and revealing errors with your counting technique

Random sample cycle counting

Let's say your warehouse has many similar items; you might randomly select and count a certain number of items during each cycle count. Randomly selecting items can help reduce the disruption of any category at once, meaning you can carry out a count during business hours.

- Best for: Warehouses containing a high quantity of similar goods

ABC cycle counting

As mentioned above, ABC cycle counting uses the ABC inventory management technique and Pareto principle to classify items in A, B, or C categories based on value. This approach counts A items more frequently than B and C items.

- Best for: Focusing on products with the greatest impact on your business

7. Use order tracking

Whether you manage stock through a spreadsheet or software, careful order tracking is essential. Organizing your data into accessible lists lets you filter orders that:

- Have been paid

- Haven't been paid

- Are overdue

- Haven't been fulfilled yet

Recommendation: With order tracking, you'll have a clear view of order statuses and a better handle on order fulfillment overall. Additionally, you can update your customers each step of the way. Work with your IT staff and management to build order tracking into your core business model.

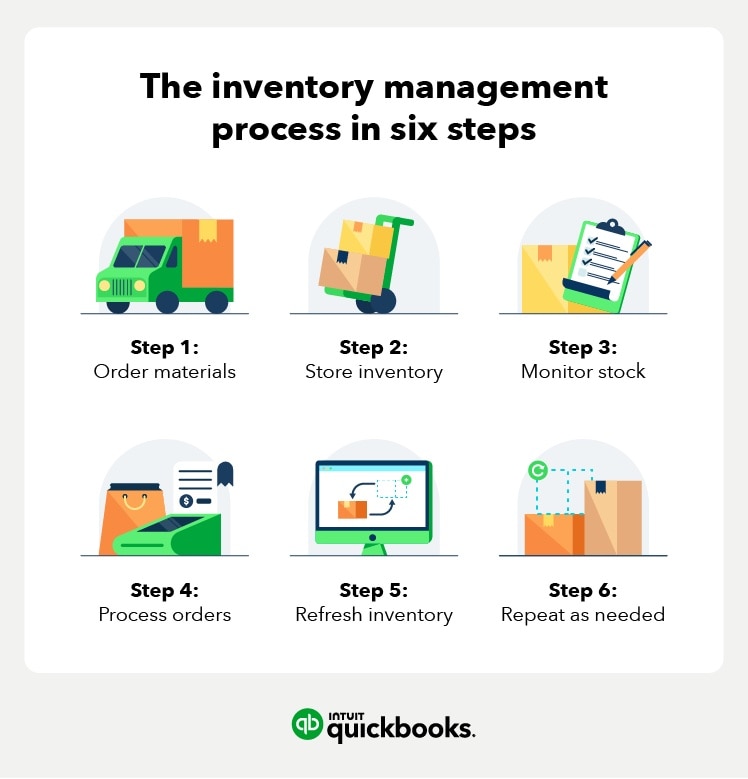

8. Focus on consistency and process

Consistent inventory processes will help your business run smoothly, especially if you manage more than one team. Inconsistency leads to inaccurate data, uneven stock levels, and displeased customers. For the best coverage, build processes around:

- Managing physical inventory

- Updating inventory tracking

- Restocking

- Adding new inventory to your site

Recommendation: Establish an inventory process that everyone can follow and understand. To ensure everyone reads it, put it in an accessible location like the employee handbook.

9. Streamline internal communication

Mistakes often come from poor communication. Streamlining contact between your employees keeps everyone on the same page and reduces errors. Keep your team in the loop by giving them the information they need when they expect it.

Recommendation: Reach out to employees with real-time status updates and periodic action emails. Depending on how your business runs, you can send these action emails weekly or daily. In other cases, a text or phone call should communicate last-minute updates.

10. Use multi-channel inventory management

Multi-channel inventory management is crucial if you sell your products across many online channels. Each new channel adds complexity to your process. An inventory management system connects all of your sales channels to one inventory hub.

Let's say you sell an item on Shopify; once you ship the item, the inventory quantity will decrease on Shopify. However, you’ll need to update the inventory levels on your other sales channels. Updating your stock every time an order ships is daunting, especially as you grow your business.

Recommendation: A multi-channel system streamlines updates and cuts down on issues that occur when the stock level is incorrect. Use your management system to note stock level changes as they happen. This improved inventory management will let you focus on running more aspects of your business.

11. Implement new Inventory management techniques

As your business grows, you should research new inventory strategies. Even though some methods will fit your model better than others, each offers its own benefits. Some popular techniques and terms include:

- ABC analysis: Comparing your most and least popular products

- Batch tracking: Grouping similar goods to track expiration dates and defective items

- Bulk shipments: Purchasing, storing, and shipping products in bulk

- Consignment: Paying for supplies after your inventory sells

- Cross-docking: Removing warehousing from your process by unloading items directly to a supplier or delivery truck

- Dropshipping: Asking supplies to ship items directly to your customer

- Lean manufacturing: Removing waste and products that don't provide value from your system

- Safety stock: Keeping extra stock of your products in case you can't resupply them

- Stock keeping unit (SKU) number: Assigning a product number that tracks stock levels and differentiate products

Recommendation: Experiment with these ideas in a limited capacity to see how they meet rising demand. Once you’ve found all the ideas that work for your business, try combining them.